Strategy

Think projects holistically, act methodically

We listen and ask. In order to advise our customers in the best possible way, it is important to us to understand their individual problems and wishes. Only with this knowledge and our experience can we optimally advise our customers. Because not everything that is technically feasible is meaningful and necessary.

The machine operator is always the focus of attention. His findings from daily work with the machines often provide important information for optimization. The consideration of work processes and the working environment is incorporated into the design of new machine developments. Only those who enjoy working with their tools are prepared to work productively at the highest level in the long term.

Technology

New possibilities

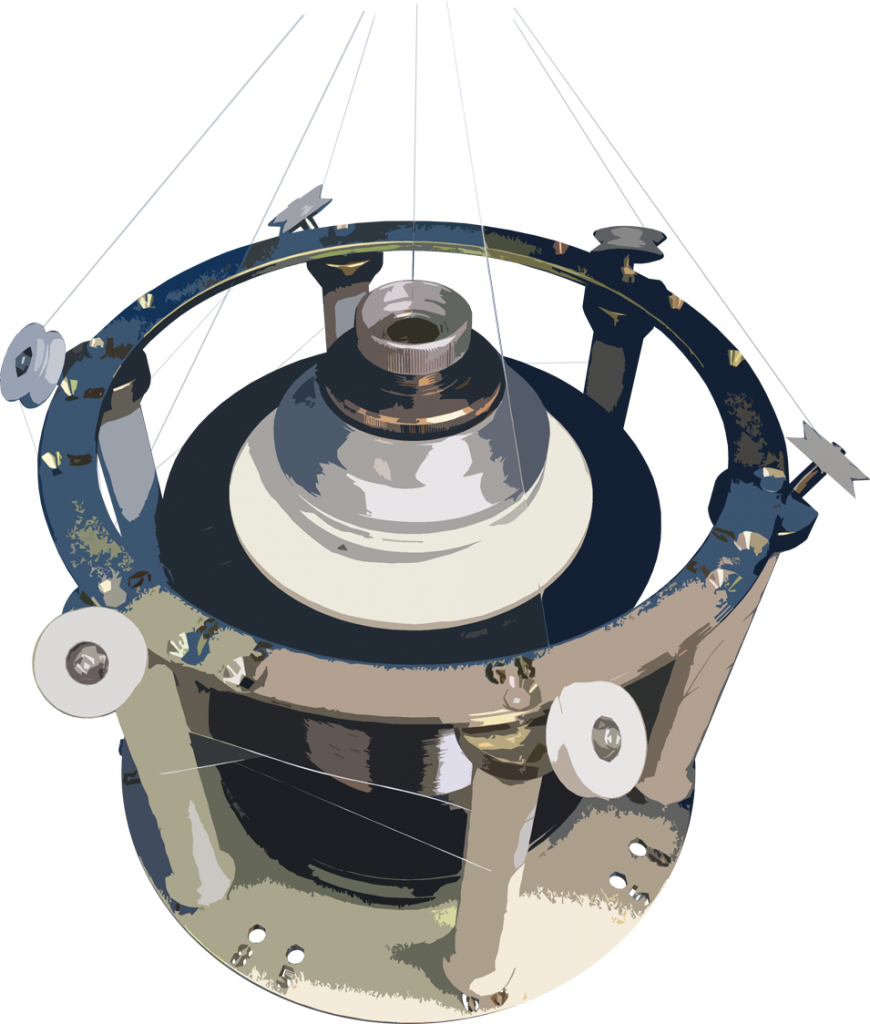

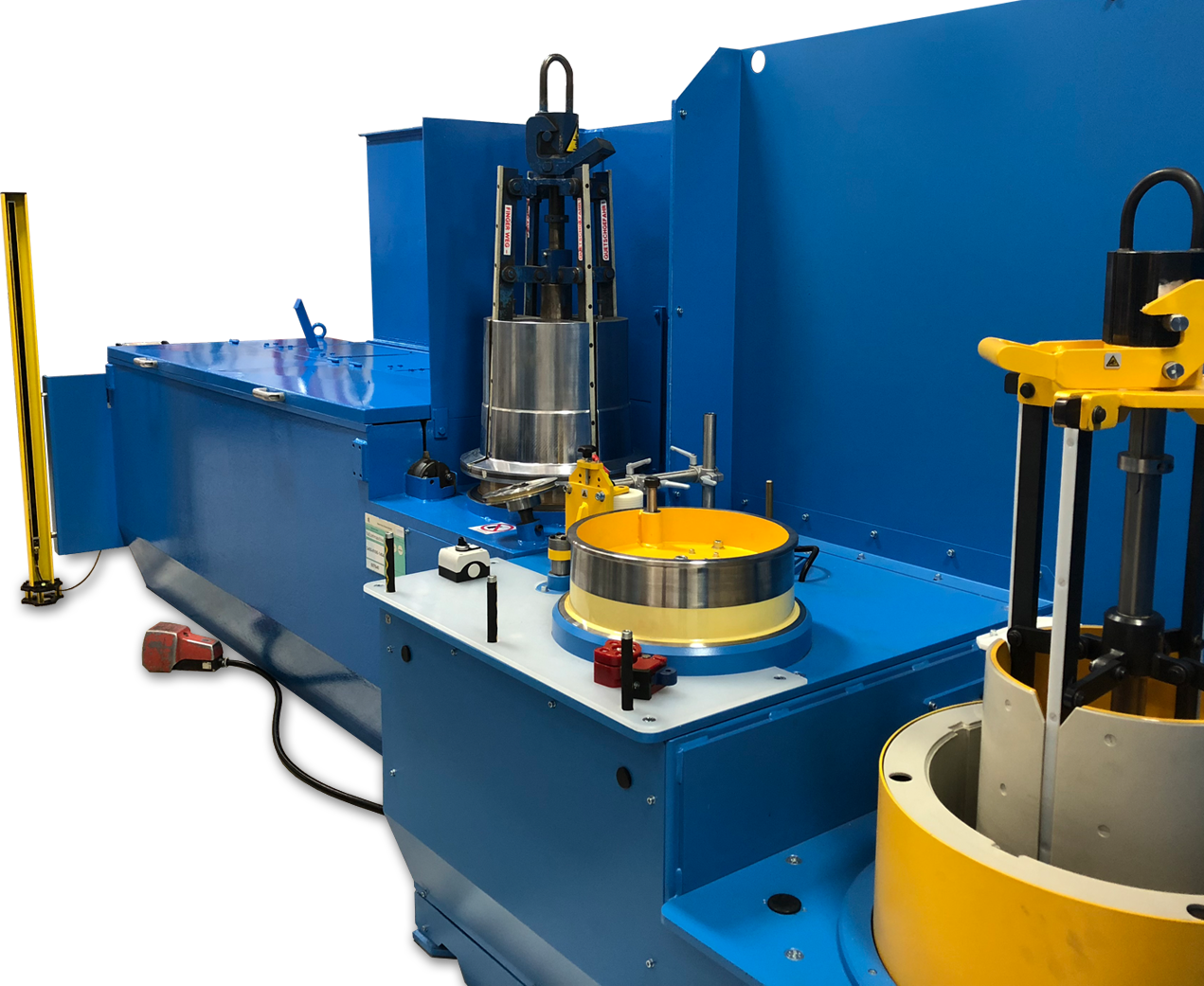

For many of our customers, specialization plays an increasingly important role in differentiating themselves from the competition in the global market. We supply you with the necessary tools to ensure that you are well equipped for the future. Our own research projects and cooperation with technical colleges and universities ensure that we have access to the latest technologies and manufacturing processes.

The use of state-of-the-art control technology ensures an increase in efficiency through higher productivity with a lower error rate and downtimes.

Das Handbuch ist zweisprachig in deutscher und englischer Sprache erschienen und kann unter der folgenden Adresse bestellt werden.

Das Handbuch ist zweisprachig in deutscher und englischer Sprache erschienen und kann unter der folgenden Adresse bestellt werden.